Since its inception in 2004, Nyalt Precision has become a global leader in tight-tolerance CNC machining for OEMs in countless industries. By integrating our modernized CNC machining centers with industry-leading CAD/CAM software, Nyalt can offer OEMs tight-tolerance machining on complex part designs and variable volume production runs. With the capability to hold tolerances as tight as 0.0005” or 12 microns, Nyalt has solidified its status as a premier provider of tight tolerance CNC machining for OEMs. This page will provide more information on how Nyalt achieves such tight tolerances on prototyping or low volume production runs, the value of tight tolerance CNC machining for OEMs, and how to work closely with Nyalt on your next machining project.

Achieving Tight Tolerances on CNC Machining Projects

Achieving a tight tolerance with CNC machining isn’t quite as simple as programming a machining center with the provided design and having it produce a final product. Tight tolerances, especially the stringent measurements offered at Nyalt Precision, result from a multi-step process and considerable validation through the machining process. Detailed below is more information about our process and how our experienced team can offer tight tolerance CNC machining for OEMs.

- Step One – 3D Modeling & Prototyping: The process of achieving tight tolerances begins with detailed and highly accurate 3D models. Our goal at Nyalt is to provide individualized attention to each client and ensure the final 3D model accurately reflects their part’s concepts, specifications, and tight tolerances. Using state-of-the-art CAD/CAM software, we can optimize the part design for manufacturability and ensure our CNC machining centers can achieve the intended tolerances.

- Step Two – CNC Machining: Once the design is finalized, it moves to the machining centers responsible for tight-tolerance CNC machining for OEMs. We have an expansive array of well-maintained CNC vertical milling and CNC turning centers from industry-leading brands Makino and Okuma. These machines and their supplemental upgrades can take the source material and machining it down to extremely tight tolerances of up to five microns or 0.0002”.

- Step Three – Grinding: In select cases, the vertical milling or turning equipment may not be able to achieve the required tolerances across surface faces or contours and require additional grinding to match product specifications. Nyalt Precision offers surface, cylindrical, and centerless grinding to help support our tight-tolerance CNC machining for OEMs. Our unique combination of machines and accessories allows us to meet increasingly demanding tolerances within two microns or 0.00008”, depending on the source material.

- Step Four – Final Finishing & Assembly: Now that your parts are machined with exacting precision, the final step in guaranteeing they have the requisite tight tolerances is any finishing or assembly procedures. To help save our customers time and costs, our experienced team will complete any final assembling or finishing steps and deliver final products ready for their end application.

50 to 55 HRc Tool Steel A2, Reversing Shafts with Harmonic Revolutions with tolerances + 0.000” / – 0.001”

The Value of Tight Tolerance CNC Machining for OEMs

Original equipment manufacturers rely on machine shops across the globe for their experience in tight-tolerance CNC machining. There is considerable value for OEMs to outsource their CNC machining projects to knowledgeable providers like Nyalt Precision.

- Operational Flexibility: Rather than worry about managing their in-house CNC machining procedures when production volumes fluctuate, OEMs can rely on trusted machine shops like Nyalt to adapt to new orders while maintaining tight tolerances.

- Reduced Costs: It is far less expensive for OEMs to outsource their CNC machining projects to specialized machine shops than to maintain in-house equipment and machinists. Not to mention the overhead costs of inventory, machine upkeep, electricity demand, and all other supplemental equipment and technical knowledge.

- Expedited Time to Market: Nyalt Precision specializes in tight tolerance CNC machining for OEMs on prototyping or low volume projects that help allow them to reduce their production time and be faster to market.

- Trust the Experts: Rather than spend years building in-house understanding and knowledge of the intricacies behind tight tolerance CNC machining, OEMs can trust the experts at Nyalt to deliver products that match increasingly complex design specifications

By outsourcing their needs for tight tolerance CNC machining, OEMs can help reduce their financial overhead and maintain flexibility in their production volume while focusing on their core services and providing a premium quality product to their customers.

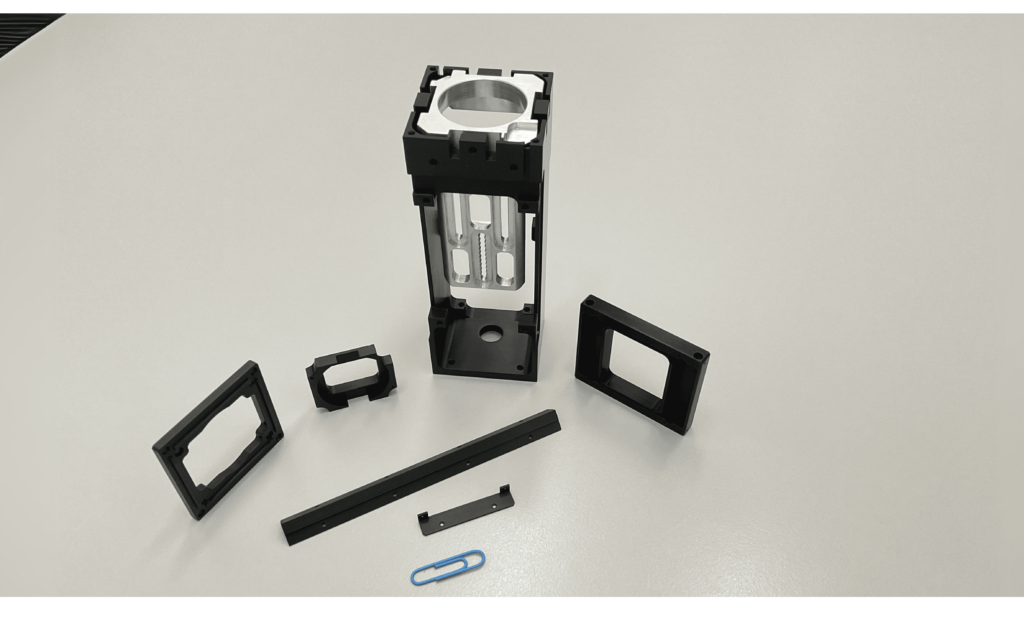

Aluminum 7075 Camera Housing & Components & a Black Anodize Finish with CNC machining tolerances

+/- 0.020 mm

Request a Quote from Nyalt Precision

When OEMs require tight-tolerance CNC machining, Nyalt Precision stands out as a trusted partner committed to providing precision, reliability, and efficiency to any industry. With a proven machining process refined through cutting-edge technology, experienced craftsmanship, meticulous attention to detail, and backed by ISO and AS9100 certifications, Nyalt consistently delivers parts that meet or exceed stringent design specifications. Whether you need support for prototyping, low-volume runs, or complex part designs, Nyalt Precision is equipped to help you reduce costs, increase operational flexibility, and expedite time to market. Send our team a message to partner with us and experience the value of precision machining tailored to your unique product designs.